Products

- Home

- Products

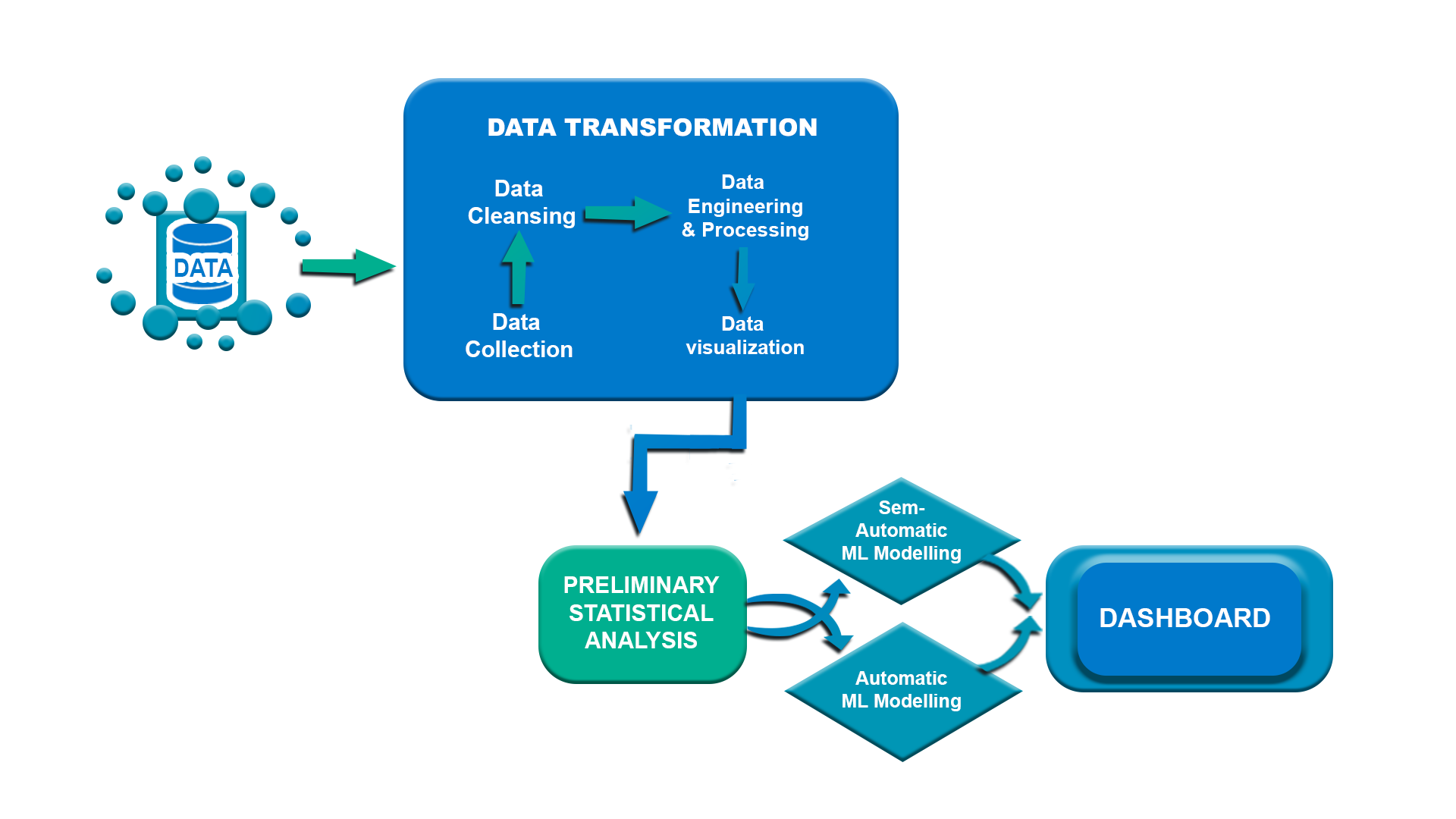

It talks to your historian, it talks to your control system, and it talks to you, fitting seamlessly into your setup. Synced with every process within your system, AIFLO combines unique machine learning models-built base-up from your plant’s historic data with real time data feeds. The outcome? Fully automated, intelligent process monitoring and control. Sensitive to every variable that theoretical models exclude including time of day, machinery performance history and ambient temperature, AIFLO accurately predicts process outcomes in a continuous plant or in a batch process, for every batch, and every production line down to the equipment level

On top of the powerful predictive model, AIFLO has its own data cleansing and processing module that organizes raw data into meaningful inputs.

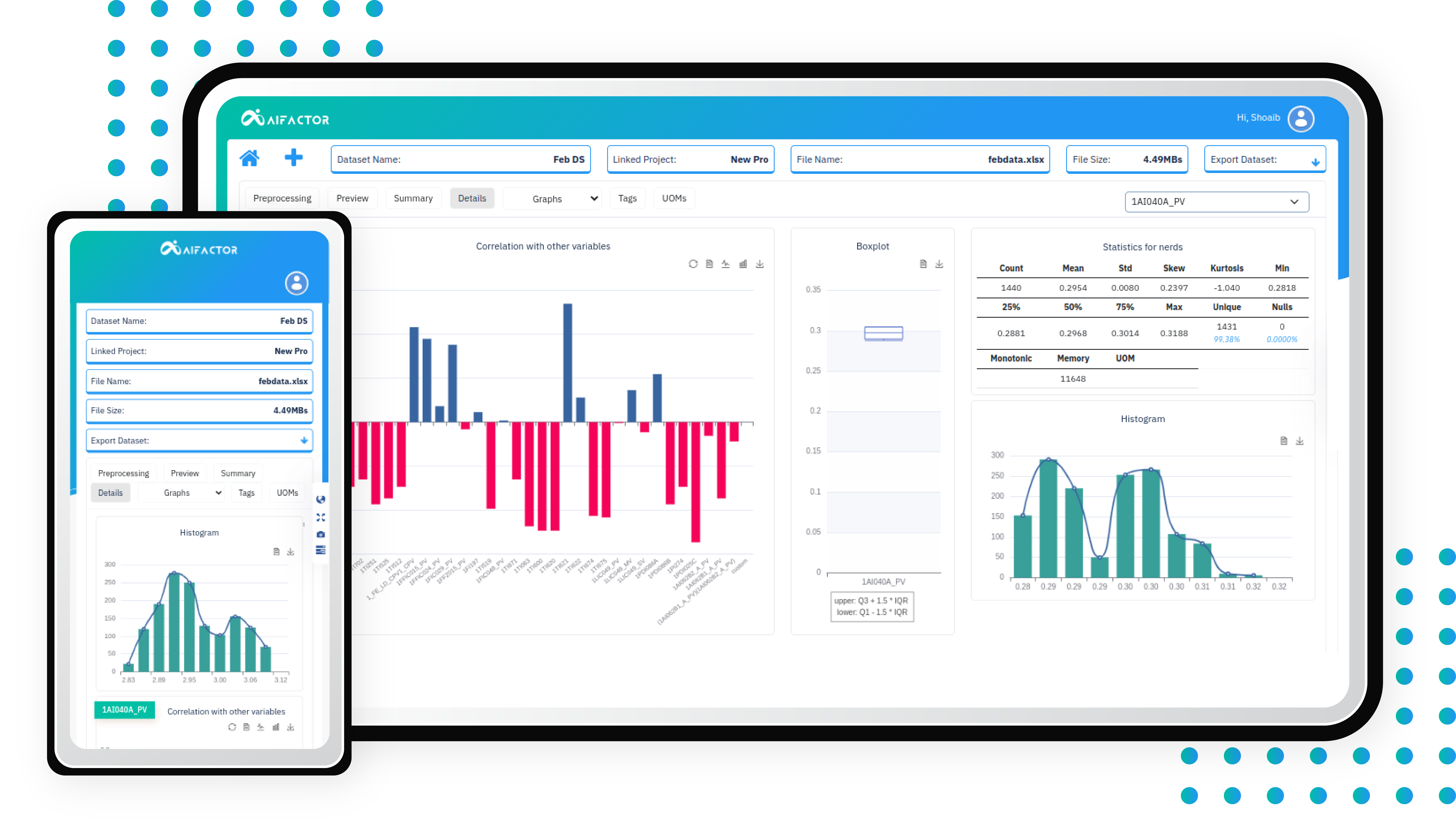

The data visualization module offers a vast variety of customizable dashboard graphics that bring to life predicted and actual trends, allowing you to effortlessly foresee areas of improvement and concern within your operation.

Want to go a step further? AIFLO is not only capable of fully controlling process variables on its own, but can also generate email and cellphone alerts for any deviations from predictions, process disturbances and data anomalies that it observes.

Contact us today and discover how AIFLO can make your business FLO better.

© 2026. All Rights Reserved by AI FACTOR INC.